What role does China PLC play in the beer production process?

![]() 2024-03-07

2024-03-07

![]() Huceen

Huceen

With the continuous improvement and improvement of China PLC, it has been widely used in many industries. Beer has always been a means of life that we cannot give up, especially in Qingdao, the hometown of Chinese beer, beer has become a necessity for the people of Qingdao. Huceen Automation's PLC has also been used wonderfully in beer processing and storage.

This should be regarded as a Chinese PLC application scenario that is closer to life. Although this bistro making craft beer looks small, it is also a small production factory. After entering, you can see the drinking area and performing arts area. , you can sing, chat, and do shows. On one side is a wine storage tank for producing beer, and on the other side is a container-style production area. Upstairs are various decks, which can be pulled wherever needed as our containers move.

Next, let’s take a look at its production process: First, there is the saccharification tank, which first crushes the malt and then puts it into the saccharification tank for saccharification. Then there is the filter tank. After filtering out the impurities, it will enter the boiling tank, and the filtered raw liquid will be processed. After boiling, the wine storage tank is finally reached. The next step is low-temperature fermentation and wine storage. You can make many wine storage tanks according to your actual needs. It usually takes 15-20 days to ferment. This is the craft beer process.

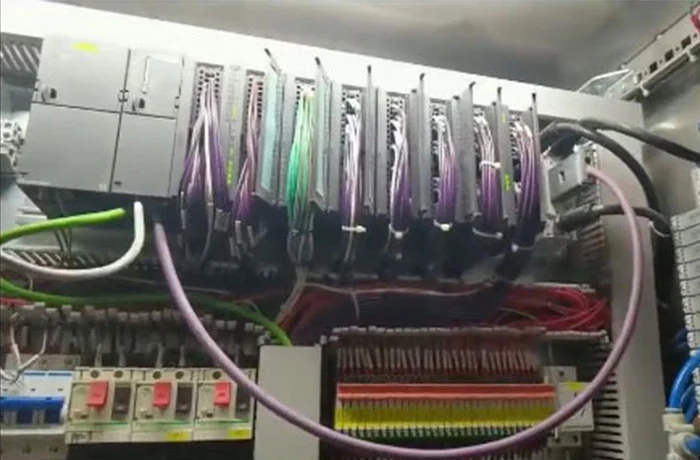

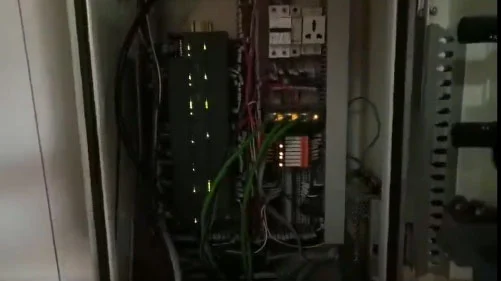

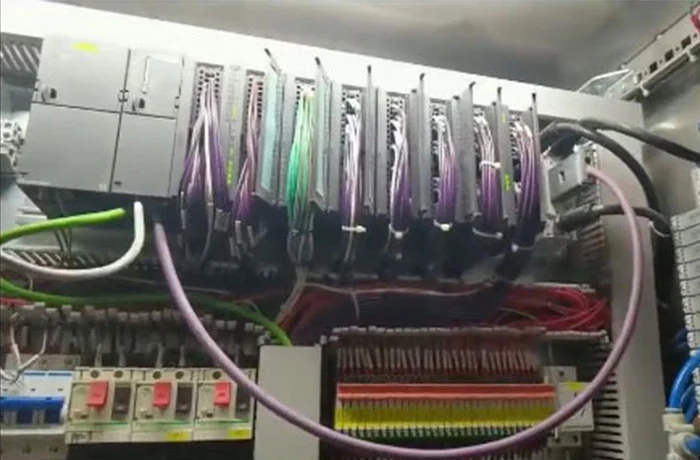

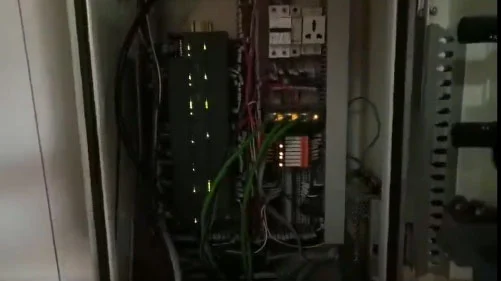

So what role does our Huceen China PLC play in this process? This is a main control system made of a foreign brand CPU and our Huceen I/O module. Based on the main control system, there are several slave stations, which use our Huceen smart series PLC. It is a set of smart PLCs that monitors the wine storage temperature, wine pressure, and wine volume as a whole.

Everyone should be aware of the application of Huceen China PLC in the craft beer industry. The manufacturer also shouted a slogan: Anyone who uses Huceen PLC will directly control the brewing of their brand of craft beer in Qingdao, haha.

This should be regarded as a Chinese PLC application scenario that is closer to life. Although this bistro making craft beer looks small, it is also a small production factory. After entering, you can see the drinking area and performing arts area. , you can sing, chat, and do shows. On one side is a wine storage tank for producing beer, and on the other side is a container-style production area. Upstairs are various decks, which can be pulled wherever needed as our containers move.

Next, let’s take a look at its production process: First, there is the saccharification tank, which first crushes the malt and then puts it into the saccharification tank for saccharification. Then there is the filter tank. After filtering out the impurities, it will enter the boiling tank, and the filtered raw liquid will be processed. After boiling, the wine storage tank is finally reached. The next step is low-temperature fermentation and wine storage. You can make many wine storage tanks according to your actual needs. It usually takes 15-20 days to ferment. This is the craft beer process.

So what role does our Huceen China PLC play in this process? This is a main control system made of a foreign brand CPU and our Huceen I/O module. Based on the main control system, there are several slave stations, which use our Huceen smart series PLC. It is a set of smart PLCs that monitors the wine storage temperature, wine pressure, and wine volume as a whole.

Everyone should be aware of the application of Huceen China PLC in the craft beer industry. The manufacturer also shouted a slogan: Anyone who uses Huceen PLC will directly control the brewing of their brand of craft beer in Qingdao, haha.

+86 13713990149

+86 13713990149 sales@huceen.com

sales@huceen.com The Application of Huceen H7-1200 Module in Automated Machine Tool Processing System

The Application of Huceen H7-1200 Module in Automated Machine Tool Processing System