Huceen Profinet Solution - Breaking Through I/O Bottlenecks and Connecting Data Islands!

![]() 2025-12-26

2025-12-26

![]() Huceen

Huceen

With the rapid advancement of urbanization, the volume of domestic sewage continues to rise, and the composition of water quality becomes increasingly complex, imposing higher demands on the automation and intelligence levels of sewage treatment systems.

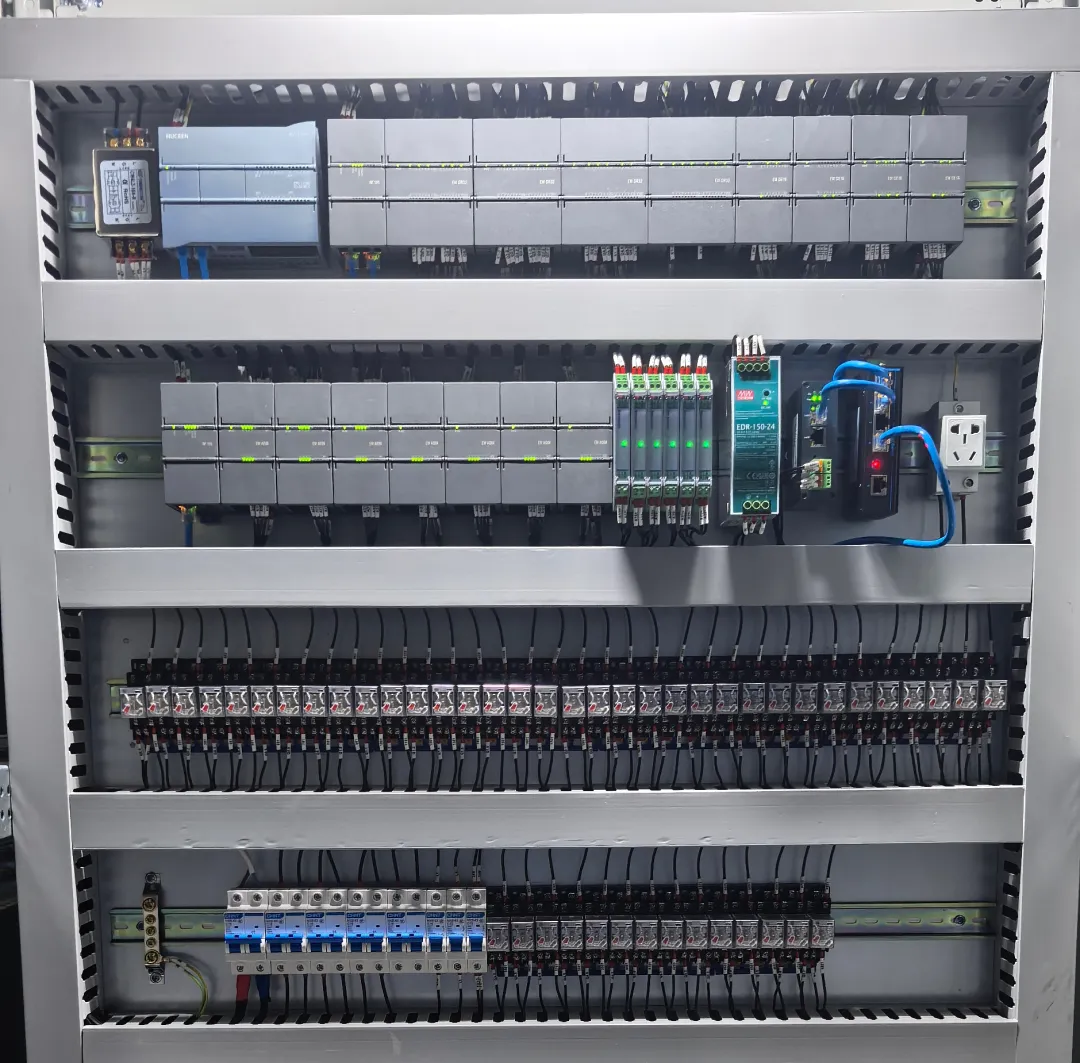

In this large-scale industrial park sewage treatment project, the system includes full-process equipment ranging from microfiltration machines, dissolved air flotation units to aeration blowers, filter presses, and UV disinfection devices.

During the planning phase, engineers faced severe challenges:

The traditional centralized expansion method can no longer meet the requirements for precise control of numerous devices and monitoring of hundreds of I/O points in various process segments.

The system needs to achieve distributed and fine-grained control over the entire process flow, which poses extremely high requirements for the controller's scalability, data processing capabilities, and network architecture.

Using traditional decentralized control or adding multiple PLC sub-stations would not only increase costs but also bring new problems such as system complexity, difficult O&M, and data fragmentation due to communication delays and protocol conversion.

Profinet Solution

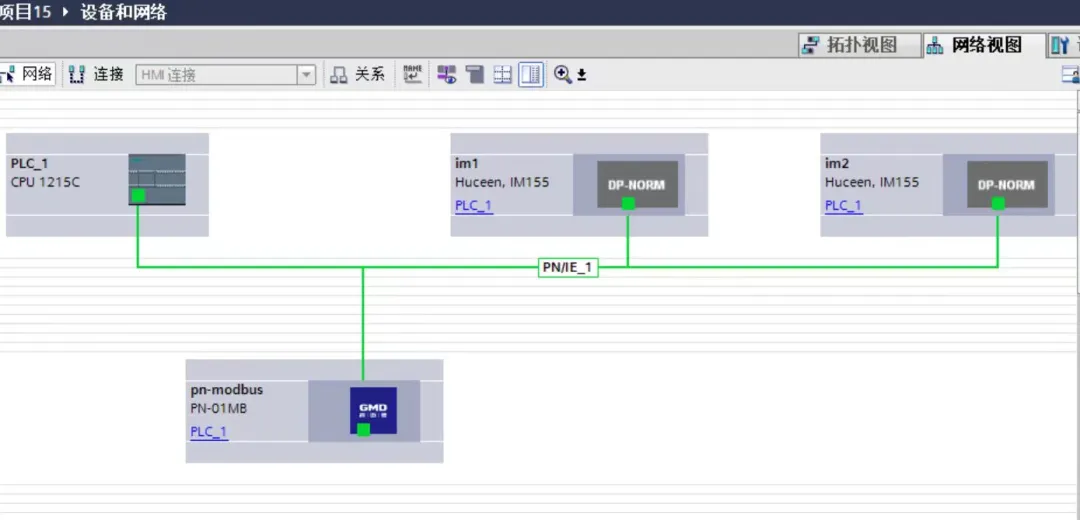

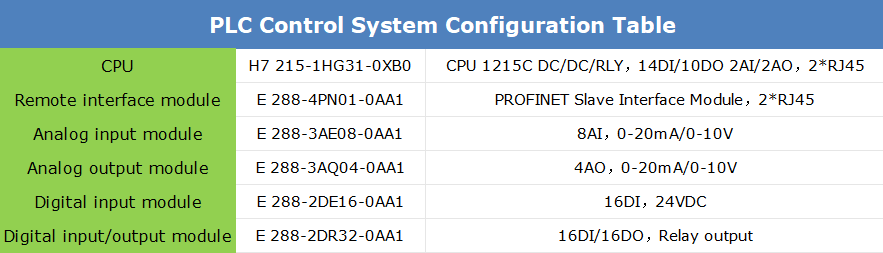

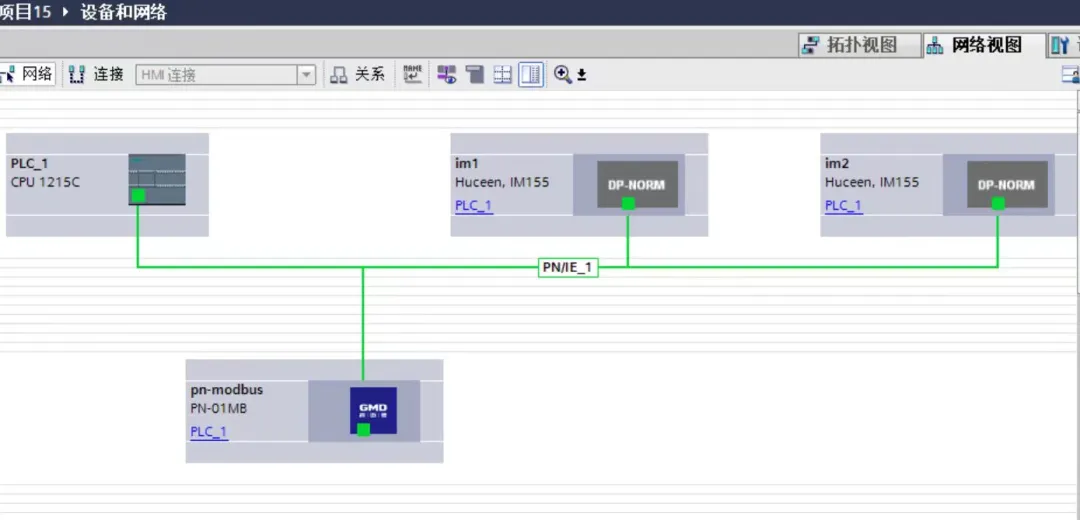

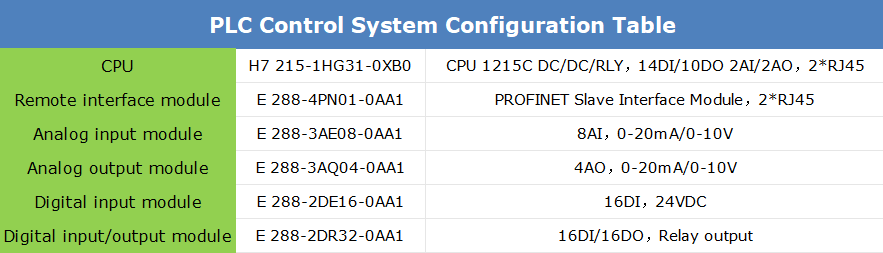

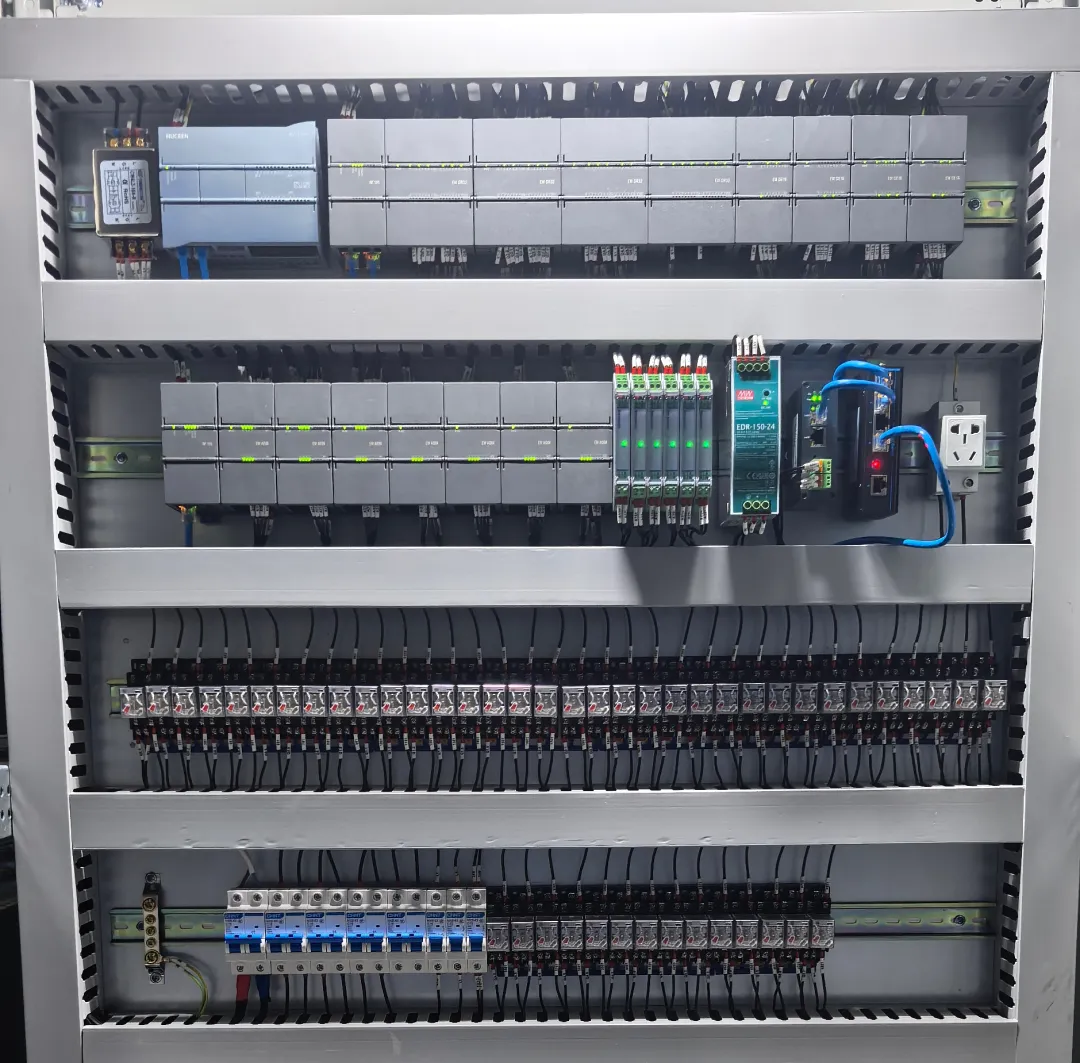

For this complex requirement, Huceen provided a Profinet solution with H7-1200 series CPU as the core and IM155 Profinet slave interface module as nodes, effectively addressing the distributed and highly reliable control needs of the sewage treatment system.

Control Core | H7-1200 Series CPU

Open Platform Supporting Future Upgrades

As a Profinet master station, H7-1200 CPU can manage not only Huceen's IM155 but also support third-party standard PN slave stations, featuring strong system openness.

In this large-scale industrial park sewage treatment project, the system includes full-process equipment ranging from microfiltration machines, dissolved air flotation units to aeration blowers, filter presses, and UV disinfection devices.

During the planning phase, engineers faced severe challenges:

The traditional centralized expansion method can no longer meet the requirements for precise control of numerous devices and monitoring of hundreds of I/O points in various process segments.

The system needs to achieve distributed and fine-grained control over the entire process flow, which poses extremely high requirements for the controller's scalability, data processing capabilities, and network architecture.

Using traditional decentralized control or adding multiple PLC sub-stations would not only increase costs but also bring new problems such as system complexity, difficult O&M, and data fragmentation due to communication delays and protocol conversion.

Profinet Solution

For this complex requirement, Huceen provided a Profinet solution with H7-1200 series CPU as the core and IM155 Profinet slave interface module as nodes, effectively addressing the distributed and highly reliable control needs of the sewage treatment system.

Control Core | H7-1200 Series CPU

The H7-1200 series CPU can simultaneously connect up to 16 I/O slave devices, fully meeting the distributed deployment requirements by process segments (pre-treatment, biochemical treatment, advanced treatment) in sewage treatment projects.

It supports large-capacity data processing capabilities for real-time data exchange of up to 4096 I/O points, ensuring stability and quick response for high-density control tasks.

Compatible with Huceen's economical HD200Smart series, high-performance compact HD200SP series, intelligent slave stations represented by E7CPU, and third-party standard PN slave stations; it provides ultimate selection flexibility and convenience for future system expansion.

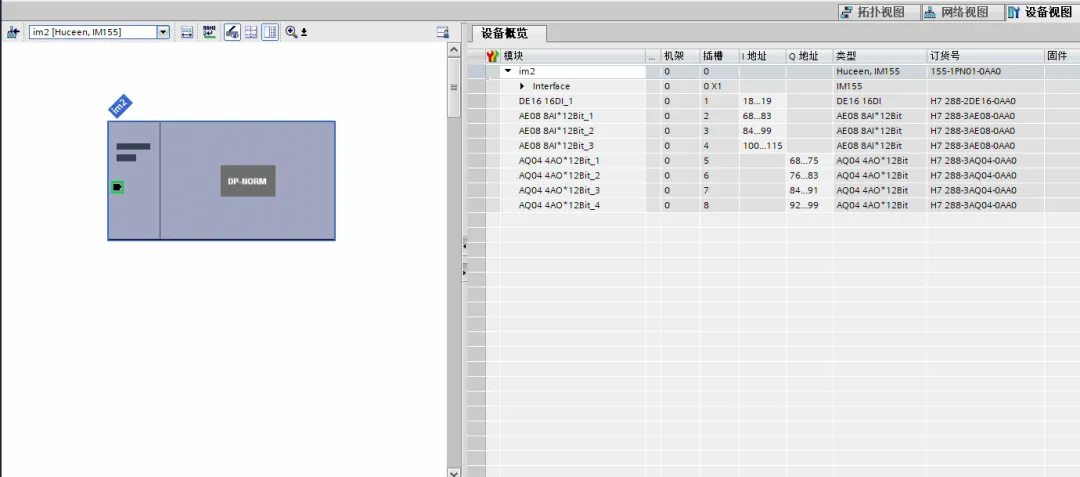

IM155 PN Slave Interface Module

It supports large-capacity data processing capabilities for real-time data exchange of up to 4096 I/O points, ensuring stability and quick response for high-density control tasks.

Compatible with Huceen's economical HD200Smart series, high-performance compact HD200SP series, intelligent slave stations represented by E7CPU, and third-party standard PN slave stations; it provides ultimate selection flexibility and convenience for future system expansion.

IM155 PN Slave Interface Module

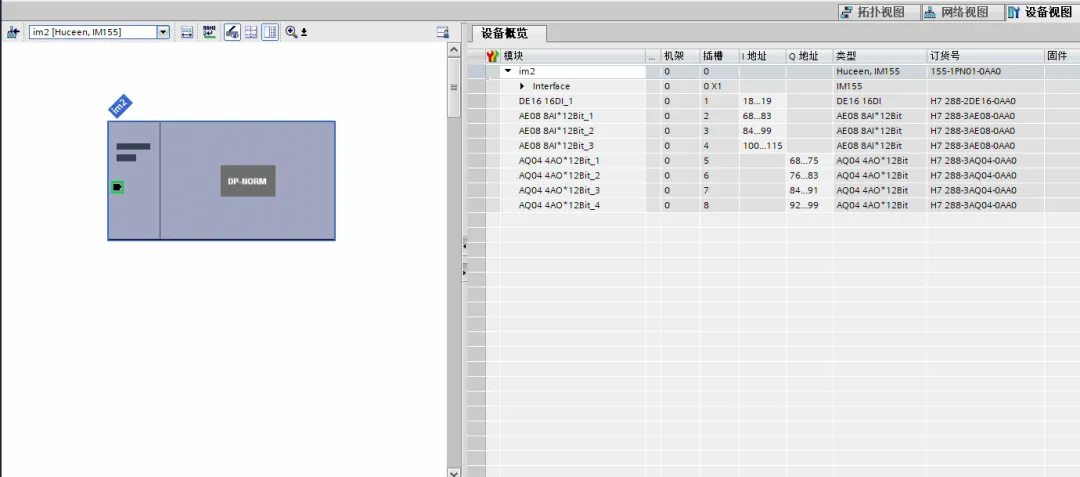

The IM155 Profinet module is suitable for scenarios where there are fewer points at many sites, which perfectly aligns with the characteristics of dispersed geographical locations of each process unit in sewage treatment plants and concentrated control points, achieving an optimal balance between cost and performance.

Each IM155 interface module can support the expansion of 16 Smart I/O modules, providing ample local point expansion capability.

The dual-port design supports building various network topologies such as star, line, ring, tree, etc., granting great flexibility in network planning.

It possesses excellent protection features including overvoltage/undervoltage protection, reverse polarity protection, and ±60V voltage resistance.

CASE STUDY

Convenient O&M, Reducing Total Cost of Ownership

The Profinet network architecture makes wiring simple, debugging and maintenance much easier compared to using multiple buses.

Engineers can perform unified configuration, programming, and diagnostics of H7-1200 and all IM155 slave stations within the familiar TIA Portal environment, significantly reducing learning and maintenance costs.

Each IM155 interface module can support the expansion of 16 Smart I/O modules, providing ample local point expansion capability.

The dual-port design supports building various network topologies such as star, line, ring, tree, etc., granting great flexibility in network planning.

It possesses excellent protection features including overvoltage/undervoltage protection, reverse polarity protection, and ±60V voltage resistance.

CASE STUDY

Convenient O&M, Reducing Total Cost of Ownership

The Profinet network architecture makes wiring simple, debugging and maintenance much easier compared to using multiple buses.

Engineers can perform unified configuration, programming, and diagnostics of H7-1200 and all IM155 slave stations within the familiar TIA Portal environment, significantly reducing learning and maintenance costs.

Open Platform Supporting Future Upgrades

As a Profinet master station, H7-1200 CPU can manage not only Huceen's IM155 but also support third-party standard PN slave stations, featuring strong system openness.

+86 13713990149

+86 13713990149 sales@huceen.com

sales@huceen.com Application of E7-200Smart PLC in stacked spiral sludge dewatering system

Application of E7-200Smart PLC in stacked spiral sludge dewatering system