Application of E7-200Smart PLC in stacked spiral sludge dewatering system

![]() 2024-01-05

2024-01-05

![]() Huceen

Huceen

In the field of sludge dehydration, stacked screw sludge dehydrators and plate and frame filter presses are two types of equipment that are widely used. The stacked screw sludge dehydrator is widely used in municipal sewage treatment projects as well as petrochemical, light industry, chemical fiber, papermaking, and pharmaceuticals due to its small space, easy maintenance and replacement, small weight, easy transportation, and self-cleaning. , leather and other industrial industries' water treatment systems.

Project Introduction

This project is a snail-stacking dehydration system for a water plant, which includes two snail-stacking sludge dehydrators, an integrated dosing device, a dosing pump, a cleaning pump, a mud storage tank, and other equipment. The system has functions such as automatic operation, equipment failure interlocking, and liquid level interlocking, which can achieve efficient sludge dehydration.

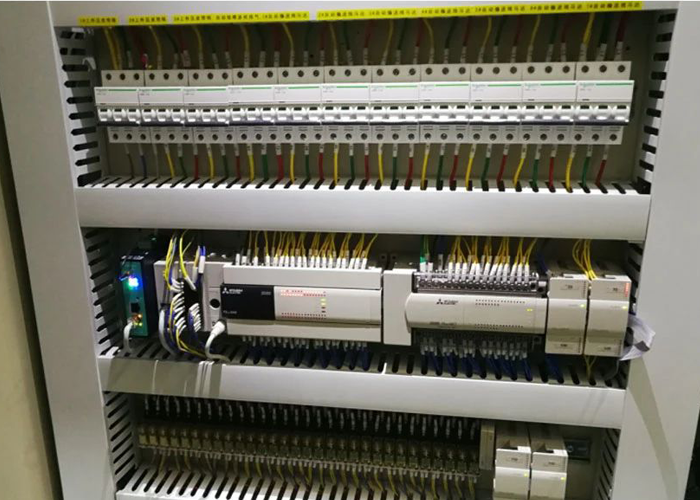

PLC control system configuration

The main control system uses Huceen E7-200SMART series PLC. The digital input of the CPU body and the extended digital input module are used to collect the operation, fault status, and liquid level switch of equipment such as mixers and valves. The digital output of the CPU body is used for control. Start and stop various equipment in the system; use the extended analog input module to collect liquid level and flow signals; use the extended analog output module to adjust the frequency of the dosing pump frequency converter.

+86 13713990149

+86 13713990149 sales@huceen.com

sales@huceen.com Application of Huceen IM155 Profinet distributed IO in MBR integrated sewage treatment equipment

Application of Huceen IM155 Profinet distributed IO in MBR integrated sewage treatment equipment