How to use PLC in spot welding machines

![]() 2024-03-12

2024-03-12

![]() Huceen

Huceen

Project Introduction

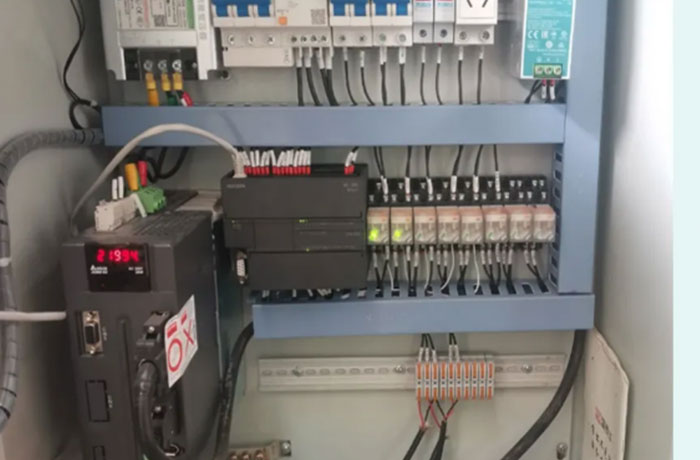

How is PLC used in spot welding machines? We have equipped this set of spot welding machine equipment with a PLC + servo positioning control system; the PLC uses Huceen 200smart CPU ST40. During production work, two workpieces of different specifications need to be welded together through the spot welding process, and according to different Product specifications the welding time as well as the welding spacing and number of welding points.

System functions

1. Manual control, manual jog control of servo motor, and manual control of spot welding machine.

2. Automatic spot welding, the equipment performs serpentine fully automatic spot welding actions based on the set "spot welding spacing", "spot welding delay", and "spot welding times".

3. Limit protection, two proximity switches are installed at both ends of the servo axis, which serve as the front and rear limits of the mechanical axis.

Application experience

1. Huceen automation complete solution has stable performance and reliability!

2. PLC development and debugging ideas are consistent with S7-200smart, engineers do not need to learn again, and the transition is perfect.

3. High cost-effectiveness, improving the price-performance ratio of customer products.

4. High-quality technical services, Huceen helps customers with a full set of services from process analysis, plan setting, and selection to product use.

Everyone should have some understanding of how PLC is used in spot welding machines. Our Huceen 200smart not only has excellent performance but is also reliable and more cost-effective. If you also need it, please contact us and we will give you a perfect solution.

+86 13713990149

+86 13713990149 sales@huceen.com

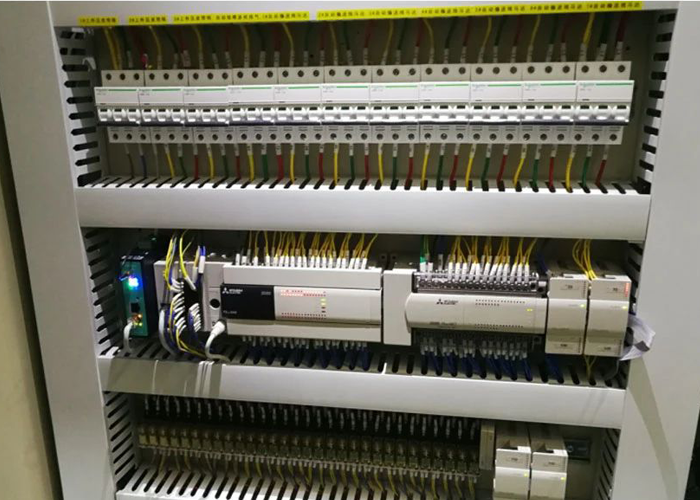

sales@huceen.com Application of Huceen 200smart PLC in SMT lead-free reflow equipment control system

Application of Huceen 200smart PLC in SMT lead-free reflow equipment control system