Application of Huceen E7-30XP Smart PLC in Hot Water Boilers

![]() 2024-01-18

2024-01-18

![]() Huceen

Huceen

Hot water boilers are mainly used for heating and bathing. The hot water boiler circulates the hot water in the insulation water tank through the hot water circulation pump, and heats the hot water in the water tank over and over again, which can achieve the purpose of bathing; the hot water boiler circulates the hot water in the heating pipe through the hot water circulation pump and passes through the radiator (radiator) It can meet people's heating requirements; hot water boilers and hot water circulation pumps can achieve the dual functions of bathing and heating in conjunction with heat exchangers.

Project Overview

This project is two sets of heating and hot water boiler control systems, including two sets of hot water boilers and corresponding circulation pumps, water replenishment pumps, and other auxiliary equipment, which can realize automatic start and stop of the equipment, PID control, interlock protection, and other functions.

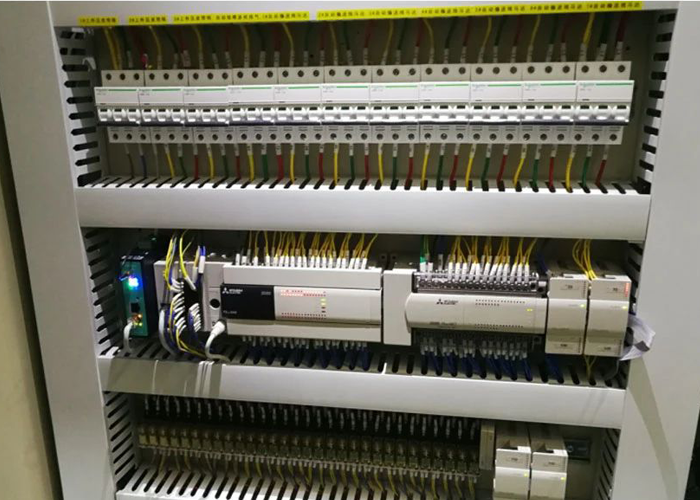

PLC control system configuration

The main control system of this project uses the unique model SR30XP of the Huceen E7-200SMART PLC series. The CPU body of this model comes with 18DI/12DO digital points and 4AI/2AO analog points, and it also comes with two independent RS485 Communication ports, suitable for a variety of applications.

The CPU is expanded with an E7-SMART series IoT board to support users' remote programming functions and can be used with the Huceen Hcloud industrial IoT cloud platform to realize cloud configuration, cloud alarm, cloud reporting, mobile phone monitoring, and other functions.

The 4 analog input channels integrated into the CPU body are used to collect the water temperature of the two boilers; the digital input is used to collect cabinet door button signals, operation/fault feedback of water pumps and fans, water tank liquid level status, and other signals. The digital output is used to collect the water temperature of the two boilers. It is used to control motors, valves, and other equipment; the main body has one RS485 communication port for Modbus RTU communication with the inverter to control the frequency of the inverter and collect the status of the inverter; the other RS485 communication port uses the PPI protocol for data interaction with the touch screen.

+86 13713990149

+86 13713990149 sales@huceen.com

sales@huceen.com Application of Huceen IM155 Porfinet Distributed IO in Cold and Heat Source Group Control System

Application of Huceen IM155 Porfinet Distributed IO in Cold and Heat Source Group Control System