Application of E7-200Smart PLC in Heat Exchange Station

![]() 2024-01-26

2024-01-26

![]() Huceen

Huceen

Function introduction of heat exchange station

Urban centralized heating system: The thermal power plant transports hot water to various heat exchange stations through the urban pipe network, and then transports the hot water to residential areas, office buildings, and other places through heat exchange units and water pumps.

The working principle of the heat exchange station is the heat source of the primary network is sent to the heat exchange station through the pipeline and enters the heat exchanger. Through the heat exchange of the heat exchanger, the heat source of the primary network is exchanged into the secondary network heating pipe. The network heating pipe is led to the heat user. The return water from the secondary network is decontaminated through the filter, enters the heat exchanger through circulation, and is heated by steam or high-temperature water for heating. After the steam or high-temperature water enters the heat exchanger, it becomes condensed water or high-temperature return water and returns to the heat source. , perform circulation of the primary and secondary network heating systems. A makeup pump pumps soft water into the system to keep the system pressure constant.

Primary network: refers to the pipe network connected between the first heat exchange station of the thermal power plant (or large regional boiler room) and the heat exchange station.

Secondary network: refers to the pipe network connected between the heat exchange station and heat users.

Project Introduction

This heat exchange station provides heating for a high-rise community and is divided into two systems: high zone and low zone according to the floor height. The high zone and the low zone share a direct supply pipe network. The water supply of the high zone system is powered by a dedicated booster circulation pump, and the water is supplied to the high zone through the water supply main pipe. Each system includes a plate heat exchanger, electric regulating valve, circulating water pump, water supply pump, primary water secondary pump, and its ancillary equipment; it can ensure winter heating of surrounding communities and commercial streets.

PLC control system configuration

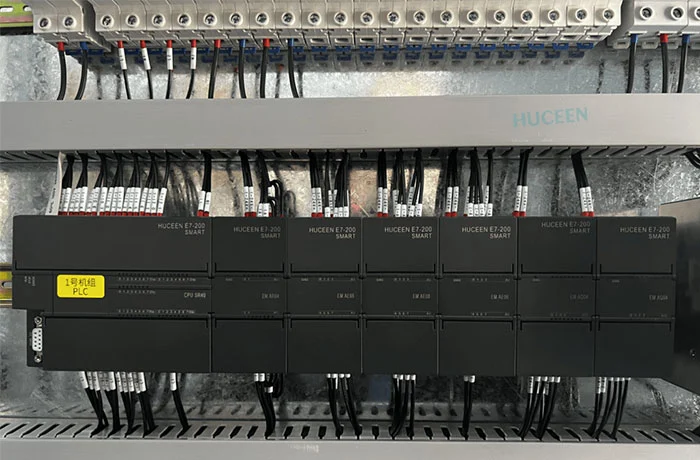

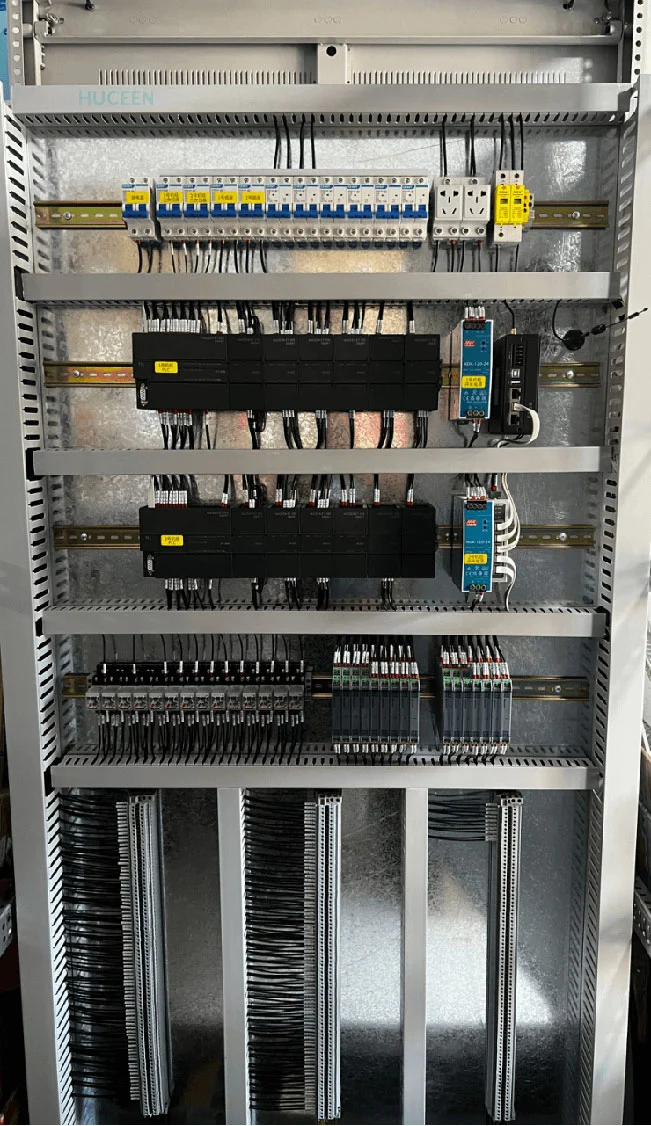

The main control system of this project uses Huceen E7-200Smart PLC, which uses the Ethernet port of the CPU body to communicate with the touch screen. The temperature of the water pipe is collected through the extended thermal resistance simulation block, and the extended analog input module is used to collect the temperature and pressure of the water pipe. , as well as the current and frequency of the frequency converter; the extended analog output module is used to adjust the frequency of the frequency converter and the on-site valve opening adjustment.

The main function

Water pump rotation training: Automatic cycle switching of multiple pumps to avoid wear or corrosion of water pumps due to long-term use or long-term deactivation.

Interlocking protection: water shortage protection, water pump failure protection, frequency converter failure alarm, automatically stopping the pump when the protection is enabled, and automatically starting the water pump when the fault is eliminated.

Temperature compensation: The set temperature can be automatically adjusted according to the outdoor temperature.

Interlock protection: When automatic water replenishment is started, the equipment does not require personnel to be on duty, and the pressure of the circulation pipeline is automatically constant at the target set value.

+86 13713990149

+86 13713990149 sales@huceen.com

sales@huceen.com Application of Huceen E7-30XP Smart PLC in Hot Water Boilers

Application of Huceen E7-30XP Smart PLC in Hot Water Boilers