Application of Huceen H7-200Smart PLC in raising machine in the post-spinning finishing process

![]() 2024-03-04

2024-03-04

![]() Huceen

Huceen

Application of Huceen H7-200Smart PLC in raising machine in the post-spinning finishing process

Raising machines are also called brushing machines and raising machines. They are widely used in woolen fabrics, Raschel warp knitted blankets, tricot warp knitted brushed fabrics (such as short velvet), and weft knitted terry brushed fabrics—fuzzing of fabrics (such as polar fleece, sweatshirt cloth), etc. Since raising is a post-finishing process for fabrics, raising directly affects the style and quality of the fabric, and raising problems are difficult to repair. Therefore, the raising process has become an important part of quality control for many manufacturers. At present, raising machines all over the world have planetary structures. Fabric raising is a dynamic physical change process. The raising style and quality are the combined effects of many parameters of the raising machine (including machine structural parameters, card clothing selection, machine operating parameters, etc.) the result of.

Project Introduction

This project is a production line for the finishing process of printing and dyeing. The production line uses a total of 8 raising machines of the same model to raise fabrics.

Control system introduction

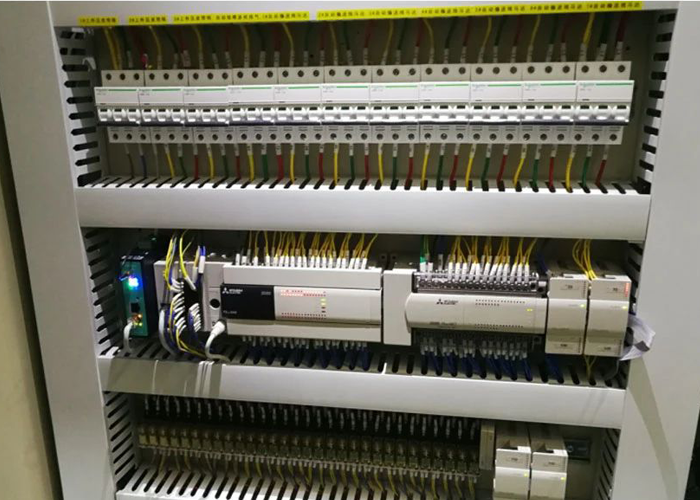

Huceen H7-200 Smart series PLC is selected for equipment control. The RS485 of the CPU communicates with the 6 inverters of the equipment through the free port protocol and sends the inverter acceleration and deceleration time setting parameters to the inverter. The Ethernet port that comes with the CPU body is used for data interaction with the touch screen. The digital input points collect equipment operation, fault and start button signals, and the digital output points are used to control equipment, cylinders, and indicator lights.

The main function

Automatic: Press the start button and the machine will start running. Press the stop button and all running machines will stop. In addition, there are fine-tuning buttons to adjust its parameters from cloth speed to counter-needle. If you want to set a certain parameter, you must first press the parameter to be adjusted to bring up the keyboard. Use the keyboard to set this parameter. Finally, the process confirmation button must be pressed to confirm that the parameter setting is valid.

Manual: The manual screen is set with front pulling, rear pulling, cloth discharging, clockwise, counterclockwise, start and stop buttons. There are forward and reverse conversion buttons for clockwise and counterclockwise respectively.

Cloth leading: The cloth leading screen has two buttons for forward cloth leading and reverse cloth leading. When the forward cloth leading start button is pressed, the machine will pull the cloth forward, and when the reverse cloth starting button is pressed, the machine will pull the cloth backward. Press the stop button and all running machines will stop.

+86 13713990149

+86 13713990149 sales@huceen.com

sales@huceen.com Application of 200smart plc cpu ST40S in mask machine

Application of 200smart plc cpu ST40S in mask machine