Application of E7-SMART PLC in plastic dehumidification dryer

![]() 2024-03-02

2024-03-02

![]() Huceen

Huceen

Dehumidification and drying equipment processing technology

1. Automatic pumping: the raw materials are pumped into the equipment bin through the pumping motor, and stops when the dehumidification bin is full;

2. Drying chamber heating: Heat the dehumidification chamber, detect the temperature in the chamber through a thermocouple, and then use PLC to perform PID calculations. The calculation results are output to the solid-state relay through the Q point of the PLC, and then the solid-state relay controls the electricity in the chamber. heater;

3. Regeneration filter: The regeneration filter needs to be rotated at a fixed speed to ensure uniform processing (so a stepper motor is needed, which can control the speed per second);

4. Regeneration electric heating: Heating the air drawn into the regeneration filter.

5. Hot and humid air desorption: During the drying process of the material, moisture will evaporate and combine with the air in the warehouse. The hot and humid air needs to be desorbed. The hot and humid air in the warehouse will be extracted through the drying fan and discharged into the rotor together with the regenerated hot air. The two airflows act on the runner at the same time, and as the runner rotates, the moisture in the air is continuously adsorbed and desorbed by the regeneration air and discharged, forming stable low dew point air, which is heated When the drying temperature of the plastic is reached, it is blown into the drying barrel to form a closed cycle to dry the raw materials.

Control principle

1. PID adjustment: The temperature signal detected by the thermocouple sensor is transmitted to the PLC (AT04 module). The operator sets the temperature in the HMI. The PLC performs PID adjustment based on the set value and the actual value, controls the solid-state relay, and then the solid-state relay controls the circuit. Heat to heat.

2. Uniform processing: Control the stepper motor through high-speed pulse output, allowing the motor to rotate once per set minute to achieve uniform processing.

3. Automatic pumping: Control the start and stop of the pumping motor according to the material level signal of the silo.

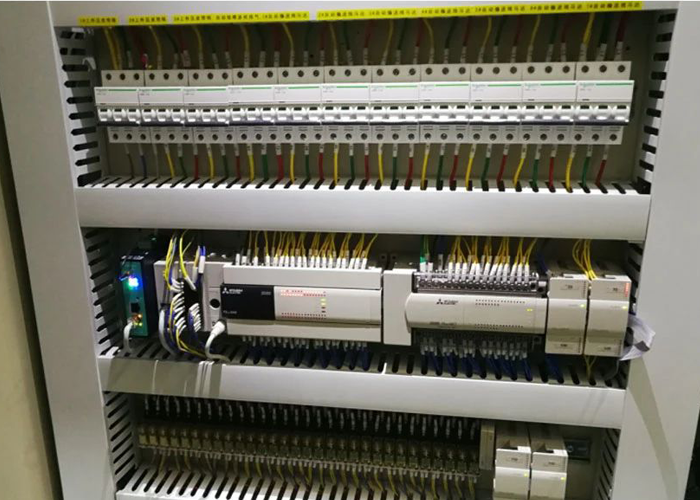

PLC configuration

| Name | Model | Remark |

| CPU | E7 288 1ST40 0AA1 | ST40, 24I/16DO RS485x1 Ethernet port x1 supports hidden encryption |

| Thermocouple module | E7 288 3AT04 0AA1 | 4CT 4-way thermocouple module |

Characteristics of E7 PLC in the case

1. The E7 series supports the "Axis Wizard" of SMART programming software

2. E7 hidden encryption function: Using the user-developed PID heating dedicated block, hidden encryption can protect the rights and interests of developers to the greatest extent. (PID is necessary in the plastic machine industry. Many experts have written libraries themselves. Hidden encryption can better protect their intellectual property rights.)

+86 13713990149

+86 13713990149 sales@huceen.com

sales@huceen.com Application of E3-200 Smart PLC in Automobile Floor mat Plastic Molding Equipment

Application of E3-200 Smart PLC in Automobile Floor mat Plastic Molding Equipment