The Application of Huceen H7-1200 Module in Automated Machine Tool Processing System

![]() 2023-12-19

2023-12-19

![]() Huceen

Huceen

Project Introduction

The communication mode between industrial robots and CNC machine tools varies depending on the different systems. For systems with more signals, communication can be achieved using methods such as fieldbus and industrial Ethernet. For systems with fewer signals, I/O signal wires can be directly used for connection, including at least door control signals, clamping signals, and processing completion signals. The project uses I/O signal cables for connection.

Robot loading and unloading sequence

In the automated machining process, the loading and unloading sequence of the robot should be: the machine tool is ready (the protective door is open, the fixture is released, and each axis is in a safe position) → the machine tool requests robot loading → robot loading → robot loading is completed → the machine tool performs automatic processing → machine tool processing is completed → robot unloading → robot unloading is completed → machine tool automatically requests loading cycle.

During processing, the operator only needs to press the machine tool start button, and the machine tool will send out a "feeding request" signal. At the same time, the robot detects whether the machine tool is in a safe position. If the machine tool is in a safe position and receives a "feeding request" signal, the robot will proceed with feeding. After the robot completes loading and completely leaves the machine tool, it will send a "loading complete" signal to the machine tool. After receiving the "loading complete" signal, the machine tool will clamp the fixture and close the protective door to start automatic processing. After the machine tool processing is completed, it automatically opens the fixture and protective door, requests the robot to cut the material, and then requests the robot to load the material after the cutting is completed, thus proceeding with the next cycle of processing。

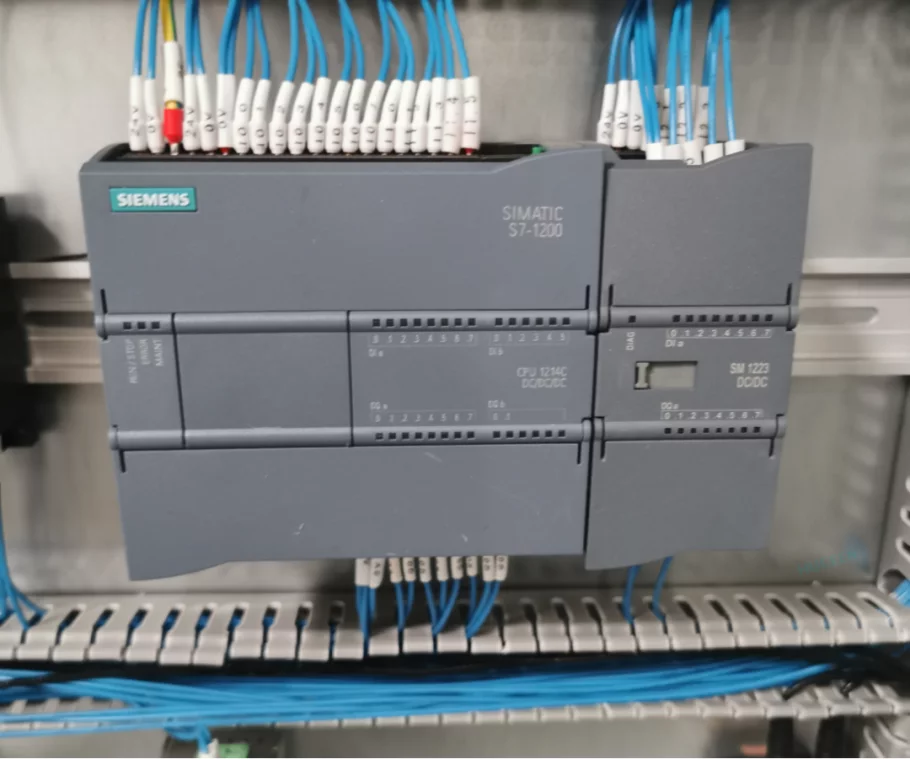

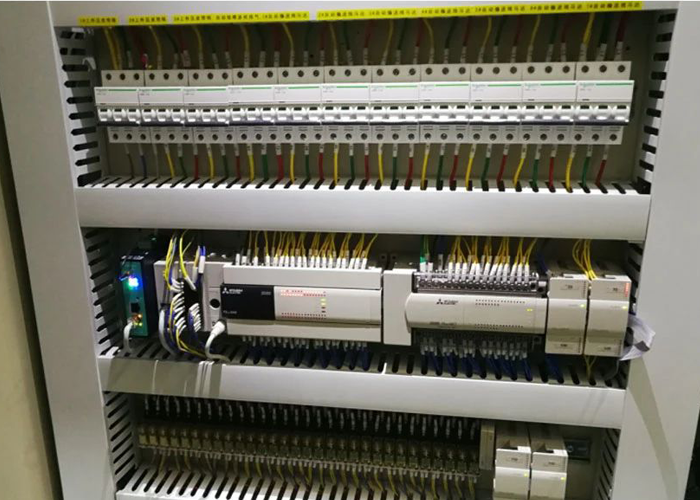

PLC control system configuration

+86 13713990149

+86 13713990149 sales@huceen.com

sales@huceen.com What role does China PLC play in the beer production process?

What role does China PLC play in the beer production process?