Application of Huceen E7-200SMART PLC in Energy Storage Battery Cabin Liquid Cooling Control System

![]() 2023-12-19

2023-12-19

![]() Huceen

Huceen

Energy storage battery compartment

Energy storage battery cabin refers to packaging large-capacity energy storage battery components in a container, which is used to store large-scale electrical energy and release it when needed. It usually consists of one or more energy storage battery modules, as well as related electronic control systems and supporting equipment. The energy storage battery cabin can store electrical energy during peak demand periods on the grid and then release it when needed to balance grid supply and demand and improve grid stability.

Here are some common uses for energy storage battery containers:

Energy dispatching and peak and valley filling: Energy storage battery cabins can store electrical energy during low energy demand periods and release electrical energy during peak periods to supply additional power demand. This can balance the load on the grid, reduce the burden on the power network, and reduce the need for backup power plants;

Backup power supply and emergency power supply: In the event of power system failure, power outage, or disaster, the energy storage battery cabin can be used as a backup power supply to provide power supply for emergency equipment or key facilities, such as hospitals, communication base stations, traffic lights, etc.;

Renewable energy storage and smooth output: The energy storage battery cabin can store the unstable production capacity of renewable energy (such as solar energy and wind energy) so that it can be released when needed. This helps solve the problem of instability of renewable energy and achieve smooth and continuous power output;

Market participation and energy trading: Energy storage battery cabins can participate in the power market and energy trading, by selling stored power when power demand peaks, or purchasing power when power demand is low, to obtain economic benefits;

Microgrid and off-grid systems: Energy storage battery cabins can be combined with renewable energy and power generation equipment to build microgrids or off-grid systems. Such systems can provide sustainable power supply in remote areas or places without grid connections, meeting local energy needs.

In short, the main purpose of energy storage battery cabins is to store electrical energy and release it when needed to balance power supply and demand, provide backup power, smooth renewable energy output, participate in energy transactions, and build microgrids or off-grid systems. These uses help improve the reliability, economics, and sustainability of power systems.

Energy storage battery cabin ambient temperature control

1. Guarantee of safe operation

With the increase in the installed capacity of energy storage power stations and the rapid increase in the scale of energy storage installations worldwide, the frequency of energy storage safety accidents has also increased significantly. Thermal runaway of lithium batteries is the main reason affecting the safe operation of energy storage power stations. Thermal runaway refers to the phenomenon that when lithium batteries encounter mechanical abuse, electrical abuse, and thermal abuse, the battery materials are damaged and generate abnormal heat. The heat continues to accumulate and eventually causes the internal temperature of the battery to rise uncontrollably. Most energy storage safety accidents occur during charging or after charging is stopped. At this time, the battery voltage is high and the battery activity is high. Circulating currents form between parallel battery clusters, causing the cells to be in an overcharged state, and the voltage rises to form an internal short circuit. Therefore It is easy to cause fire accidents.

Temperature control is an important factor in avoiding thermal runaway of lithium batteries. A reasonable and efficient thermal management system is an important method to solve the problem of thermal runaway. Through real-time detection of lithium battery status, the thermal management device can be used to control the battery core at a reasonable temperature to avoid thermal runaway.

2. Improvement of energy storage performance

Temperature is an important factor affecting battery performance. Temperature has a great impact on lithium batteries. On the one hand, the capacity and life of lithium batteries will change with temperature changes. On the other hand, high temperatures will decompose the internal materials of the battery, thus affecting the stability of the lithium battery. Considering the efficiency and safety of lithium batteries, it is generally believed that the optimal temperature range of lithium batteries is 10~35°C.

3.Energy storage battery compartment liquid cooling system

The system consists of a water circulation system, a refrigeration system, and an electronic control system. The heat of the battery core is taken out through the water pipeline, and the efficiency and power of heat transfer are improved through the water circulation system. The refrigeration system discharges the heat out of the energy storage battery compartment through compressor refrigeration. Ensure that the battery cell is in a temperature environment for optimal performance.

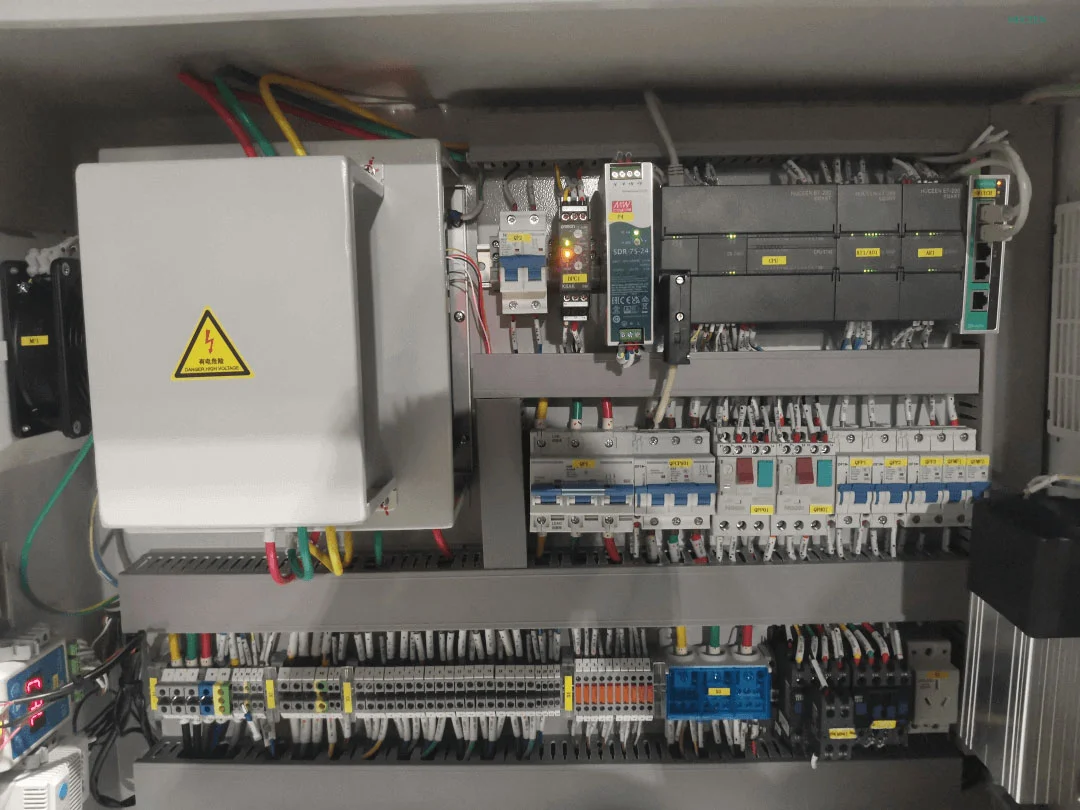

PLC control system

The main control system uses Huceen E7-200SMART PLC:

1. The RS485 communication port that comes with the CPU body communicates with the refrigeration system regulating valve controller and compressor inverter to read the adjustment opening and frequency;

2. The Ethernet port of the CPU body communicates with the touch screen;

3. By expanding the 5CM01 RS485 communication board, the temperature of the battery core can be read by communicating with the BMS system through the Modbus protocol;

4. By expanding the AM06 module, the analog input signal is used to collect the water pressure signal of the pipelines in the water circulation system and refrigeration system, and the analog output signal controls the opening of the regulating valve and the frequency of the compressor inverter.

5. By expanding the AR02 module, collect the temperature of the water supply and return pipelines in the water circulation system.

+86 13713990149

+86 13713990149 sales@huceen.com

sales@huceen.com Application of Huceen IM155 Profinet distributed IO solution in heat exchange station

Application of Huceen IM155 Profinet distributed IO solution in heat exchange station