Application of Huceen E7-200 SMART in Heat Treatment Industrial Furnace

![]() 2025-05-21

2025-05-21

![]() Huceen

Huceen

Project Introduction:

This project has successfully achieved precise control and intelligent management of gas heating furnaces in the casting industry, significantly improving production efficiency and casting quality. By finely regulating core parameters such as gas flow rate, air flow rate, and temperature, the heating, insulation, and cooling of industrial furnaces for heat treatment are ensured to be executed accurately, thereby achieving high-quality production of castings. In addition, we have fully utilized the automation and intelligence advantages of PLC to optimize the operation process of the heating furnace, simplify the operation steps, reduce human intervention, and further improve production efficiency. Meanwhile, by optimizing the control strategy, we have effectively reduced energy consumption and achieved the goal of energy conservation and environmental protection. Overall, the implementation of this project has brought revolutionary changes to the control and management of gas heating furnaces in the foundry industry, injecting new impetus into the sustainable development of the industry.

Main functional features:

(1) High precision temperature and pressure control: Huceen E7-200 SMART PLC can real-time collect and process temperature and pressure data in heat treatment industrial furnaces. By pre-set high and low threshold values, PLC can accurately control the temperature values of each channel and the pressure values of the air main pipeline and gas pipeline, ensuring that the temperature and pressure inside the furnace are always maintained within the optimal process range. This not only improves the quality stability of the castings, but also extends the service life of the heating furnace.

(2) Intelligent alarm and fault handling: PLC has a complete process quantity alarm function. When the temperature or pressure exceeds the set range, it will immediately trigger the alarm mechanism and prompt the operator through sound and light signals. At the same time, PLC can automatically take corresponding measures according to the type of fault, such as closing key components such as gas valves and fans, to avoid the expansion of accidents. This intelligent alarm and fault handling mechanism greatly improves production safety.

(3) PID automatic regulation and energy-saving optimization: The constant air pressure PID regulation of air ducts is a major highlight of this project. Through the collaborative work of wind pressure sensors and PLC, the system can adjust the frequency of the frequency converter in real time to maintain a constant pressure in the air pipeline. This PID automatic adjustment method not only improves the thermal efficiency of the heating furnace, but also reduces energy consumption costs. In addition, PLC can intelligently adjust gas flow and air flow according to the trend of temperature and pressure changes in the furnace, achieving energy-saving optimization.

(4) Automated ignition and temperature control: Before starting up, the operator only needs to set the target temperature values and gas pressure inspection parameters for each temperature zone on the touch screen. The PLC will automatically start the fan, open the gas valve, and ignite based on these parameters. During the ignition process, the PLC will automatically adjust the gas flow rate and air volume based on real-time temperature feedback, ensuring that the furnace temperature quickly reaches and stabilizes at the target value. If the temperature is too high, the PLC will automatically close the ignition valve and air valve, and re ignite after the temperature drops to a safe range. This automated ignition and temperature control method greatly improves the operational convenience and temperature control accuracy of the heating furnace.

(5) Touch screen monitoring and data analysis: In order to facilitate real-time monitoring and analysis of the operating status of the heating furnace by operators, we have equipped the system with a touch screen interface. Operators can view current temperature, pressure and other parameters through the touch screen, and query historical temperature curves and fault records. In addition, the touch screen also supports data export function, which facilitates users to conduct in-depth analysis and optimization of the operating data of the heating furnace. This real-time monitoring and data analysis function provides strong support for lean production and continuous improvement in the foundry industry.

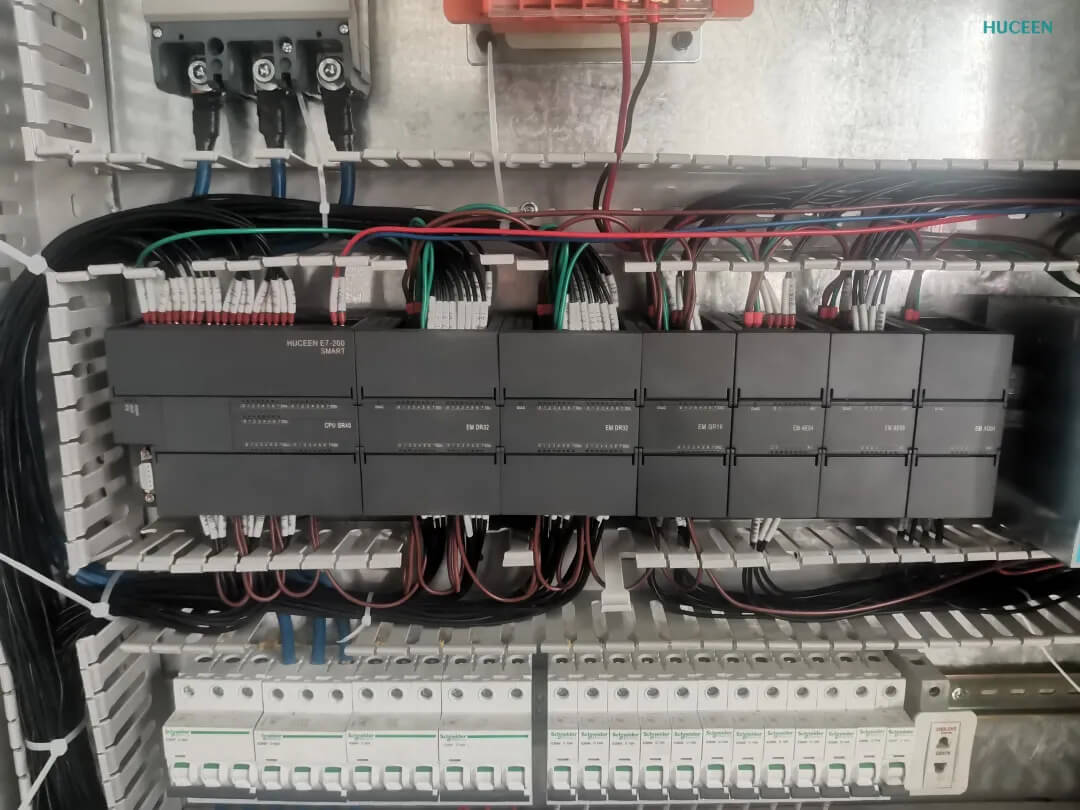

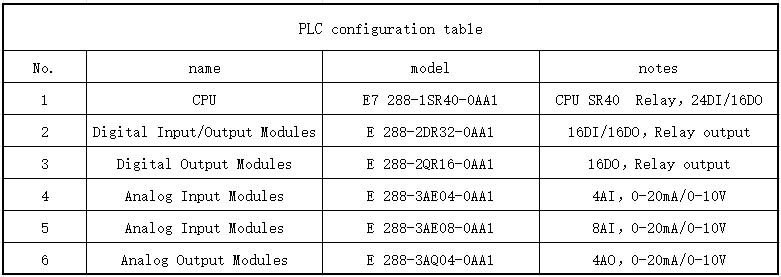

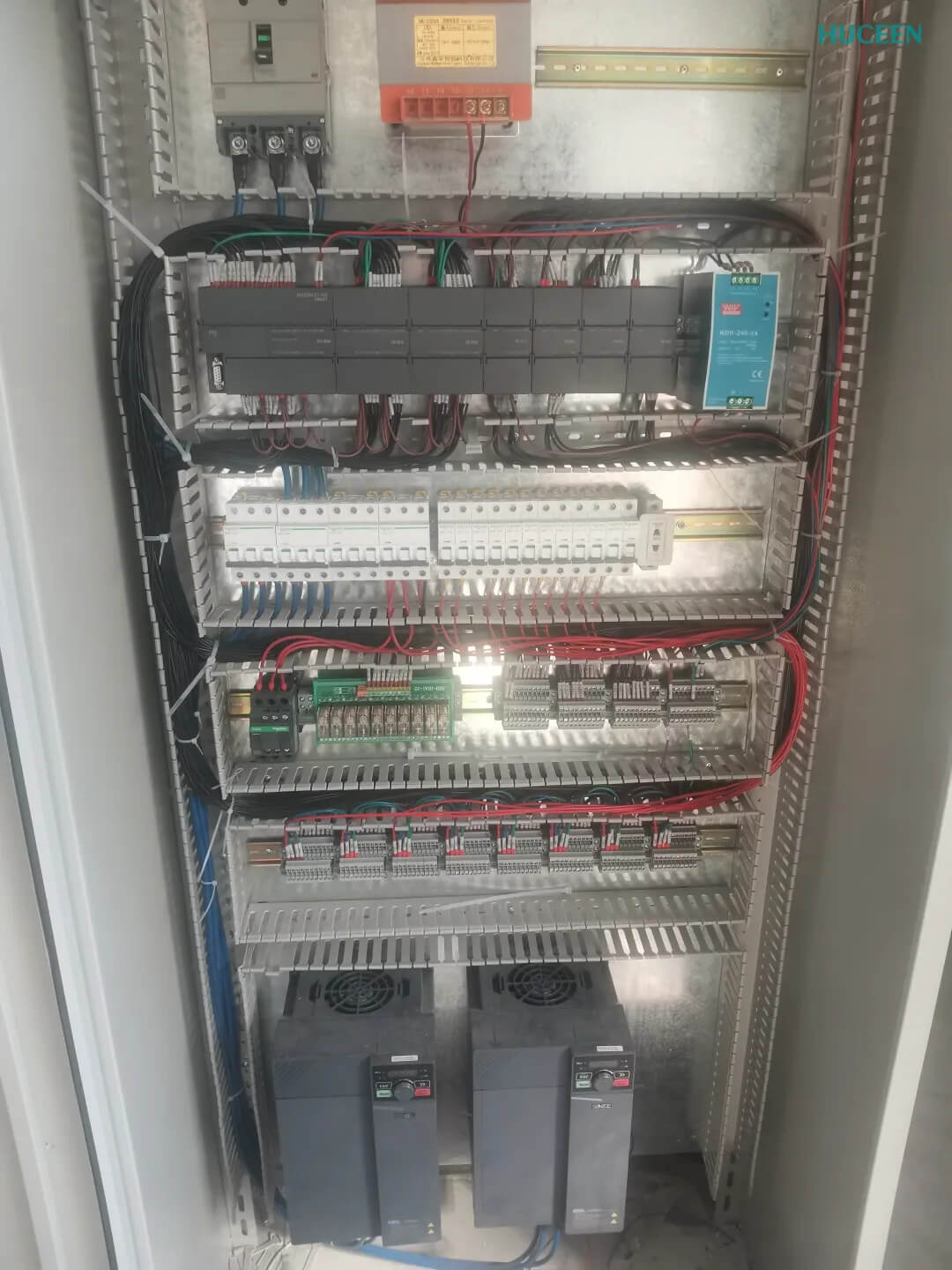

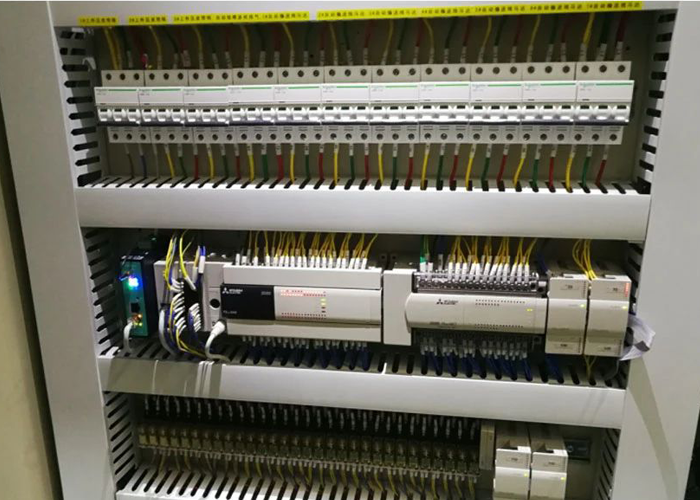

PLC control system :

+86 13713990149

+86 13713990149 sales@huceen.com

sales@huceen.com Application of Huceen H7-1200 PLC in Filter Press

Application of Huceen H7-1200 PLC in Filter Press